Your Minimum thread engagement chart images are available in this site. Minimum thread engagement chart are a topic that is being searched for and liked by netizens now. You can Download the Minimum thread engagement chart files here. Find and Download all royalty-free images.

If you’re searching for minimum thread engagement chart pictures information connected with to the minimum thread engagement chart keyword, you have come to the ideal site. Our site frequently gives you suggestions for refferencing the highest quality video and picture content, please kindly search and find more informative video content and graphics that fit your interests.

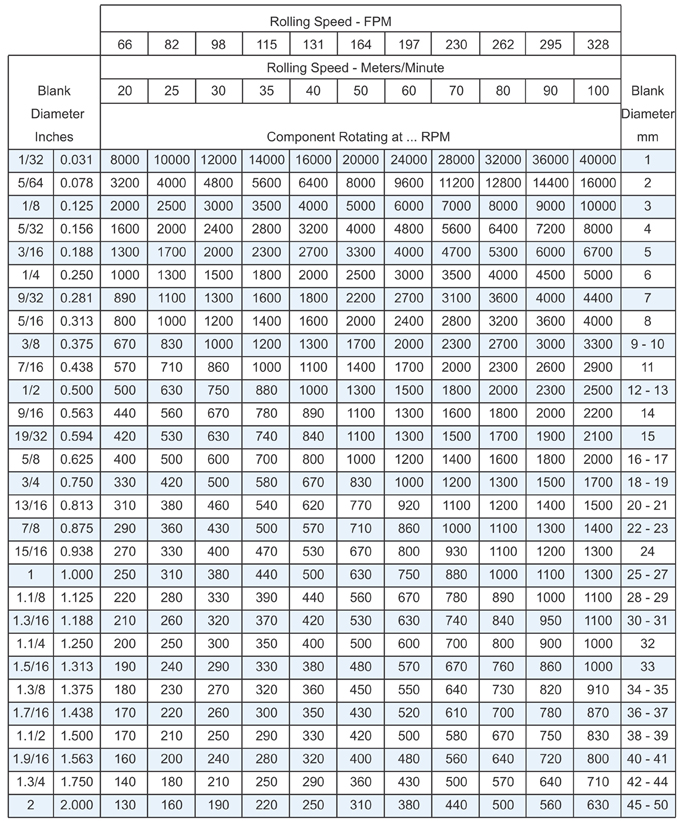

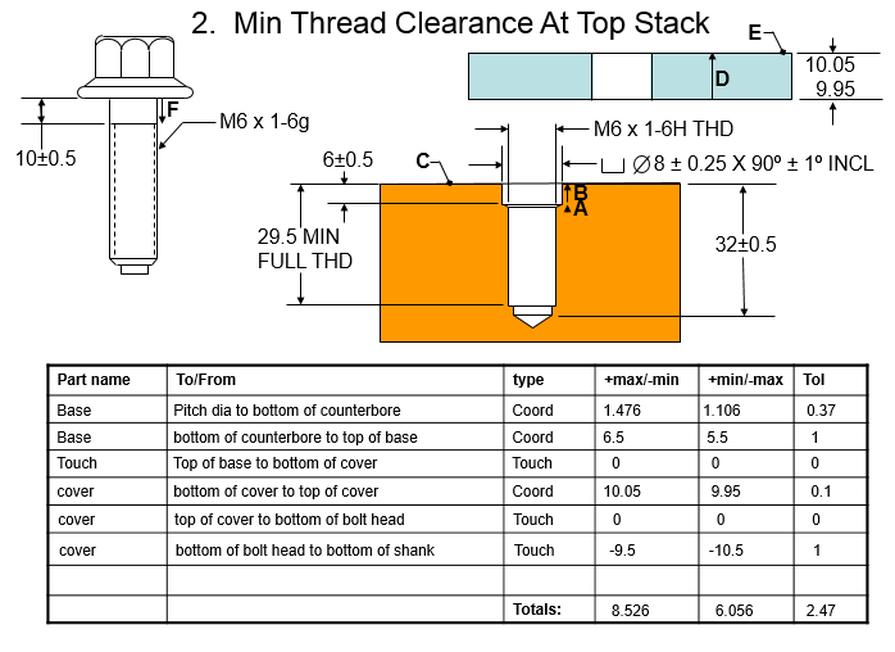

Minimum Thread Engagement Chart. Thread Size Dimension A 18 14 38 12 34 1 1-14 1-12 2 2-12 3 4 5 6 8 10 12 14 38 38 12 916 1116 1116 1116 34 1516 1 1-18 1-14. Just looking at Table PG-39 the minimum required thread engagement varies from 4 threads to 13 threads depending on pressure and pipe size. For this it is necessary the shear area of the threaded feature be at least 2 times the tensile area. Please pay attention to the definition of blind hole and through hole you can choose this in the left top corner of application.

Practical Machinist Largest Manufacturing Technology Forum On The Web From practicalmachinist.com

Practical Machinist Largest Manufacturing Technology Forum On The Web From practicalmachinist.com

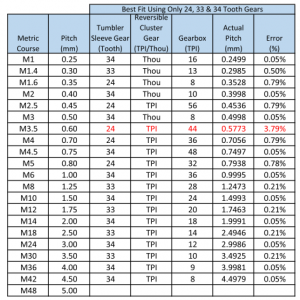

Minimum Thread Engagement Bolt Failure Chart - Standard 48 525 24 Nominal Diameter Stress Area Grade 2 Grade 5 Grade 8 Grade 2 Grade 5 Grade 8 Grade 2 Grade 5 Grade 8 in in2 in in in in in in in in in 14 - 20 0250 00318 014 023 029 013 021 027 029 047 058 516 - 18 0313 00524 019 031 038 017 028 035 038 061 077. Minimum Thread Engagement Formula and Calculation ISO The screw should fail before the thread strips. L e Minimum Thread Engagement Length A t Tensile Stress Area D Major Diameter of fastener screw p 1 Number of threads per inch n. Published on October 23 2018 Driven Products. Lug nuts lug bolts and wheel locks should always be tightened to the recommended torque specifications found in your vehicles owners manual. One diameter of engagement–if the screw is 5mm then it needs 5mm of engagement.

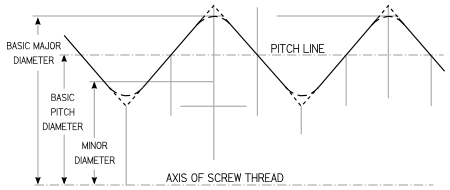

Thread Pitch Length P Pitch Diameter at External Thread Start E0 Hand Tight Thread Engagement Length L1 Diameter E1 Maximum Thread Engagement L2 Diameter E2.

Engineering Information Conversions and Calculations. Safe and proper installation requires using the correct tools and procedures. The chart at left demonstrates the loss of clamp load at a. At Begining of External Thread. Lug nuts lug bolts and wheel locks should always be tightened to the recommended torque specifications found in your vehicles owners manual. However the required min thread engagement increases and decreases dramatically with pipe size pitch.

Source: pdfprof.com

Source: pdfprof.com

The table shows for differents materials the minimum engagement depth of a threaded hole L to enable the screw fails before the thread of the hole. L e Minimum Thread Engagement Length A t Tensile Stress Area D Major Diameter of fastener screw p 1 Number of threads per inch n. At Begining of External Thread. So it is needed to define previously the characteristics ot the screw. 5 full threads 2.

Source: practicalmachinist.com

Source: practicalmachinist.com

So it is needed to define previously the characteristics ot the screw. Always utilize the minimum amount of draft possible to retain good mold function. Minimum Thread Engagement for Wheel Nuts. The optimum thread engagement is the minimum thread engagement necessary to insure that if a bolt is over-loaded either at assembly or in service and failure occurs the bolt will break rather than strip the threads of the cast iron or the bolt. Consequently to offset the possibility of interference between mating threads the minor diameters of the UNJ internal threads had to.

Source: bossard.com

Source: bossard.com

In many cases tapped hole in a softer material special alloys etc these values are not sufficient and the formulae to the right. All units shall be consistant and given in inches. Minimum Thread Engagement Bolt Failure Chart - Metric 332 362 165 Nominal Diameter Stress Area Class 88 Class 109 Class 129 Class 88 Class 109 Class 129 Class 88 Class 109 Class 129 mm mm2 mm mm mm mm mm mm mm mm mm M6 x 10 6 2013 61 77 90 56 71 83 123 155 182 M8 x 125 8 3661 83 105 123 77 96 113 168 211 248. For this it is necessary the shear area of the threaded feature be at least 2 times the tensile area. In other words it is expected that the shear failure occurs in the fastener part often externally threaded and the failure occurs only after utilizing full tensile strength.

Source: de.pinterest.com

Source: de.pinterest.com

The table shows for differents materials the minimum engagement depth of a threaded hole L to enable the screw fails before the thread of the hole. ISO Standard Thread available from M1 to M36 Property class Thread pitch fine or coarse. An old rule-of-thumb³ is that in a threaded hole in steel the length of engagement should be at least 15 times the diameter of the screw and in cast iron or brass 18 to 2 times the diameter. THREAD ENGAGEMENT LENGTH CALCULATOR. Through holes are calculated without none-effective thread end and it is a prerequisite that the screw-end protrudes with two.

Source: slideshare.net

Source: slideshare.net

Minimum Thread Engagement Bolt Failure Chart - Metric 332 362 165 Nominal Diameter Stress Area Class 88 Class 109 Class 129 Class 88 Class 109 Class 129 Class 88 Class 109 Class 129 mm mm2 mm mm mm mm mm mm mm mm mm M6 x 10 6 2013 61 77 90 56 71 83 123 155 182 M8 x 125 8 3661 83 105 123 77 96 113 168 211 248. Thread engement distance 2 x base diameter of screw or bolt. All units shall be consistant and given in inches. Thread Pitch Length P Pitch Diameter at External Thread Start E0 Hand Tight Thread Engagement Length L1 Diameter E1 Maximum Thread Engagement L2 Diameter E2. For this it is necessary the shear area of the threaded feature be at least 2 times the tensile area.

Source: pinterest.com

Source: pinterest.com

Percent of thread engagement is based size of the mating hole compared to the fastener and how much the height of threads of the screw are engaged. At Small End of Pipe a. Through holes are calculated without none-effective thread end and it is a prerequisite that the screw-end protrudes with two. In many cases tapped hole in a softer material special alloys etc these values are not sufficient and the formulae to the right. For this it is necessary the shear area of the threaded feature be at least 2 times the tensile area.

Source: dimensionalconsulting.com

Source: dimensionalconsulting.com

At Small End of Pipe a. Overall Length External Thread L4 b. I was always taught two rules of thumb not from the same people though for minimum engagement 1. Minimum Thread Engagement for Wheel Nuts. All units shall be consistant and given in inches.

Blind holes should be at least half a diameter deeper than the length of engagement. The screw should fail before the thread strips. Consequently to offset the possibility of interference between mating threads the minor diameters of the UNJ internal threads had to. It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a tapped hole is approximately 1 times the nominal diameter in steel and 2 times the nominal diameter in aluminum. Always utilize the minimum amount of draft possible to retain good mold function.

Source: pinterest.com

Source: pinterest.com

So it is needed to define previously the characteristics ot the screw. At Begining of External Thread. Please pay attention to the definition of blind hole and through hole you can choose this in the left top corner of application. The thread engagement length will often in praxis be reduced due to run-in and run-out of screw and threads as well as chamfers. Minimum Thread Engagement for Wheel Nuts.

Source: pinterest.com

Source: pinterest.com

Just looking at Table PG-39 the minimum required thread engagement varies from 4 threads to 13 threads depending on pressure and pipe size. It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a tapped hole is approximately 1 times the nominal diameter in steel and 2 times the nominal diameter in aluminum. At Small End of Pipe a. Follow the specific boss design recommendations listed for. Generally the nominal hole size hø is calculated at a depth equal to half of the fasteners total length of engagement L not including the counterbore.

So it is needed to define previously the characteristics ot the screw. For this it is necessary the shear area of the threaded feature be at least 2 times the tensile area. Consequently to offset the possibility of interference between mating threads the minor diameters of the UNJ internal threads had to. I agree that 7 threads is a good rule of thumb. An old rule-of-thumb³ is that in a threaded hole in steel the length of engagement should be at least 15 times the diameter of the screw and in cast iron or brass 18 to 2 times the diameter.

Source: engineersedge.com

Source: engineersedge.com

E1 Length L2 Dia. 2012-03-08 steris Mechanical 8 Mar 12 1239. An old rule-of-thumb³ is that in a threaded hole in steel the length of engagement should be at least 15 times the diameter of the screw and in cast iron or brass 18 to 2 times the diameter. Please pay attention to the definition of blind hole and through hole you can choose this in the left top corner of application. The guide takes into consideration.

Source: slideshare.net

Source: slideshare.net

An old rule-of-thumb³ is that in a threaded hole in steel the length of engagement should be at least 15 times the diameter of the screw and in cast iron or brass 18 to 2 times the diameter. Safe and proper installation requires using the correct tools and procedures. I agree that 7 threads is a good rule of thumb. An old rule-of-thumb³ is that in a threaded hole in steel the length of engagement should be at least 15 times the diameter of the screw and in cast iron or brass 18 to 2 times the diameter. One diameter of engagement–if the screw is 5mm then it needs 5mm of engagement.

Source: bossard.com

Source: bossard.com

Minimum Thread Engagement for Wheel Nuts. One diameter of engagement–if the screw is 5mm then it needs 5mm of engagement. For this it is necessary the shear area of the threaded feature be at least 2 times the tensile area and gives the Minimum value of thread engagement length to make the tensile area determinative for the load at which the. Assuming the threaded feature is of the identical material. Overall Length External Thread L4 b.

Source: slideshare.net

Source: slideshare.net

Why is Thread Engagement important. Consider the formula below defining the. 5 full threads 2. For example a 10-24 thread forming screw will have around 80 thread engagement in a 1683 hole while around 70 thread engagement in a 1710 hole. I agree that 7 threads is a good rule of thumb.

Source: pinterest.com

Source: pinterest.com

Minimum Thread Engagement Formula and Calculation ISO The screw should fail before the thread strips. Blind holes should be at least half a diameter deeper than the length of engagement. Normal Engagement Length of NPT Thread in Inches A Dimensions given do not allow for variations in tapping or threading. The answer is. Minimum Thread Engagement Formula and Calculation ISO The screw should fail before the thread strips.

Source: pdfprof.com

Source: pdfprof.com

An old rule-of-thumb³ is that in a threaded hole in steel the length of engagement should be at least 15 times the diameter of the screw and in cast iron or brass 18 to 2 times the diameter. Generally the minimum thread engagement length for a joint is determined such that the full tensile strength of the bolt is utilized prior to shearing of nut threads. An old rule-of-thumb³ is that in a threaded hole in steel the length of engagement should be at least 15 times the diameter of the screw and in cast iron or brass 18 to 2 times the diameter. Assuming the threaded feature is of the identical material. Minimum Thread Engagement Bolt Failure Chart - Standard 48 525 24 Nominal Diameter Stress Area Grade 2 Grade 5 Grade 8 Grade 2 Grade 5 Grade 8 Grade 2 Grade 5 Grade 8 in in2 in in in in in in in in in 14 - 20 0250 00318 014 023 029 013 021 027 029 047 058 516 - 18 0313 00524 019 031 038 017 028 035 038 061 077.

Source: portlandbolt.com

Source: portlandbolt.com

National Standard Taper Pipe NPT Threads Size Chart 116 03125 27 016 02611 18 0405 27 018 4½ 2½ 026 14 054 18 02 4 3 0401 38 0675 18 024 4½ 3 0408 12 084 14 032 4½ 3 0534 34 105 14 034 4½ 3 0546 1 1315 115 04 4½ 3¼ 0682 1¼ 166 115 042 4½ 3¼ 0707 1½ 19 115 042 4½ 3¼ 0724 2 2375 115 0436 5 3 0756. One diameter of engagement–if the screw is 5mm then it needs 5mm of engagement. The screw should fail before the thread strips. Overall Length External Thread L4 b. 2012-03-08 steris Mechanical 8 Mar 12 1239.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title minimum thread engagement chart by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.